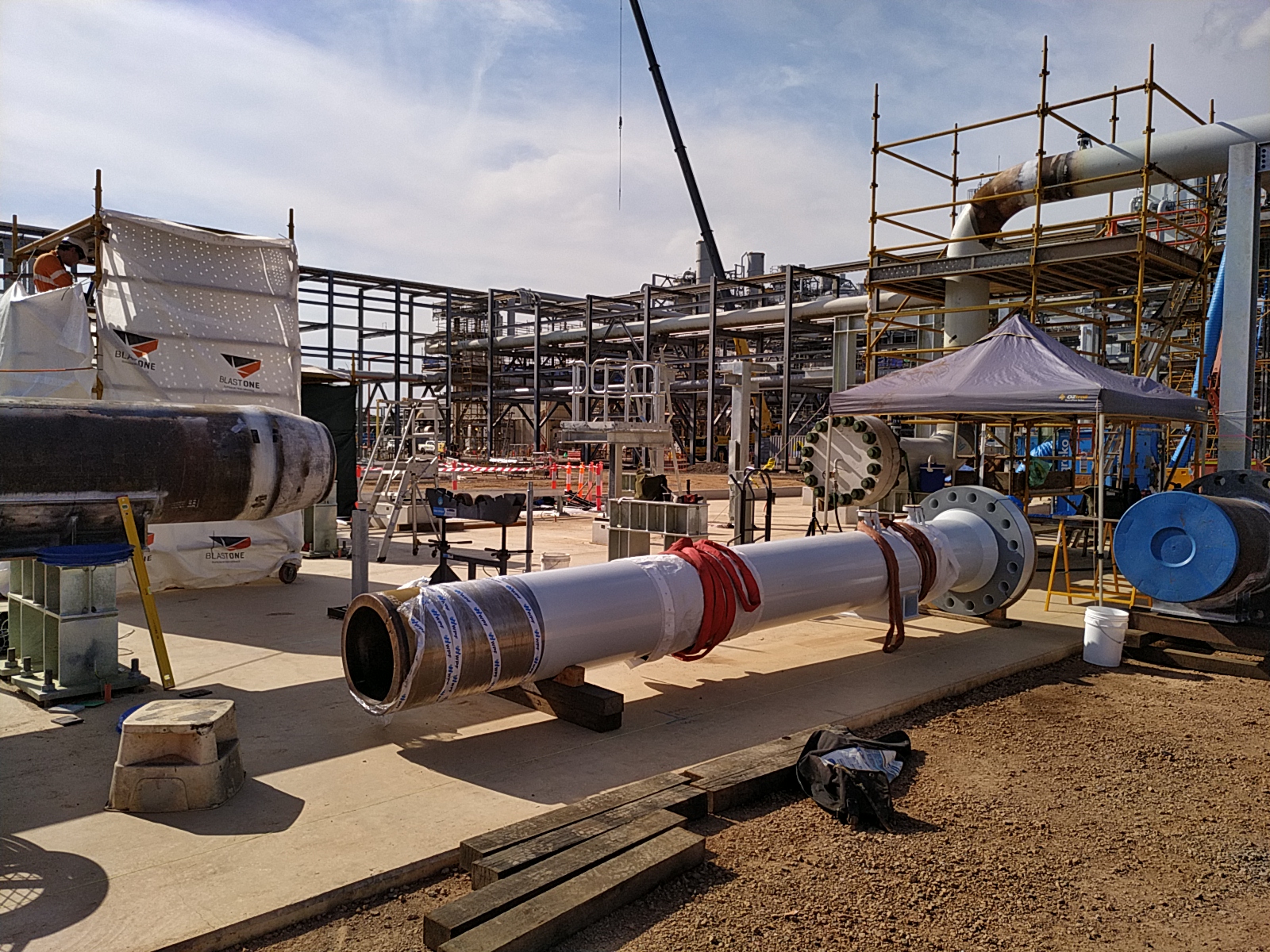

Darwin Pipeline Duplication (DPD) Project at the Darwin Liquefied Natural Gas (DLNG) Facility

2024-2025

Location: NT

Client: Santos / NACAP

Sector: Energy

As a trusted supplier, WPF Duratec were engaged by Santos to deliver on a high risk / critical path project.

The challenge was to fabricate 50T of structural steel concurrently with 250T of pipe spooling in a small-time window. WPF were requested to accelerate the delivery schedule and reacted accordingly, by utilising 2x workshop locations (NT & WA) running around the clock shifts to ensure tight schedules could be met. The request then came through to assist in the installation of the piping tie-ins and WPF Duratec successfully mobilised 80x personnel to Darwin including equipment within a 2x week window. The campaign was successful; schedule was achieved & we are proud of a 0% DNC site rate and being LTI free.

- Concurrent night and day shift fabrication completed in Naval Base & Darwin workshops to ensure faster turnaround.

- Workshop fabrication consisting of welding, PWHT, NDT, hydrostatic testing and surface treatment.

- Successfully completed 15x AS2885 and 11x ASME B31.3 PQRs offsite

- Fabrication and welding of 250 tonnes of large bore, heavy wall carbon and stainless-steel pipe spooling.

- Fabrication of approximately 50 tonnes of structural components.

- <1% overall failure rate

- 80x personnel mobilised to site within 2 weeks

- 12x week site campaign to accelerate delivery schedule

- Site installation & tie in welding of pipe spooling in accordance with AS2885 & ASME B31.3

- LTI-free

- Completed project 2x weeks ahead of schedule & under budget