TRANsFORMING COMPLEX DESIGNS, BUILT TO LAST

Our fabrication of specialised components and structures are tailored to the unique requirements of our clients, engineered to perfection and built to last.

With our skills and experience in maintaining, upgrading and refurbishing key assets, you can benefit from minimal production losses while deferring the costs of new asset investment.

Our specialty areas

Get in touchSpecialising in pipe spooling, fabrication and site services that are focused on delivering fully integrated solutions to clients, WPF have the capacity to install, service and repair equipment across a range of sectors.

Our expert welding engineers create certified welding procedure specifications (WPS) to ensure compliance with industry standards such as ASME, AWS, and ISO. From standard materials to exotic metals, our procedures optimise welding techniques. Whether for new construction, repairs, or specialised fabrication, we ensure that every welding process is meticulously designed to enhance performance, reduce costs, and meet stringent quality control measures.

WPF offer advanced welding techniques. Our capabilities include specialised TIG, SAW, Hyperfill, ring groove and sleeve overlay welding.

We are also experienced in submerged arc welding of tubular materials such as marine drilling risers, structural and conductor casing and pipeline welding, including “hot tap” welding on live gas pipelines. Additionally, we can provide Inlay welding and weld build ups using parent metal or corrosion resistant alloys such as Inconel 625. This is done using a semi-automatic TIG process.

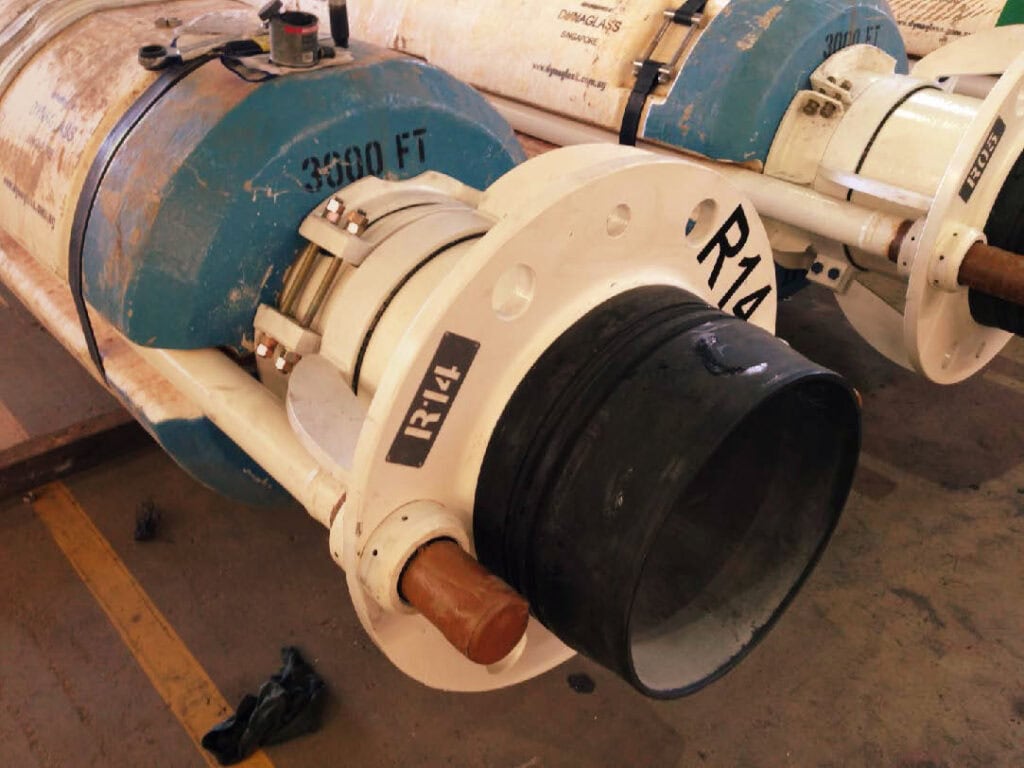

We have extensive experience in the fabrication, refurbishment and recertification of all capital drilling equipment. We provide all forms of mechanical repair work, spare parts and replacement products as well as certified design engineering and machining, metal fabrication, coded welding, sandblasting and spray painting.

This is inclusive of:

- Disassembly

- Cleaning

- Inspection and disposition

- Repair

- Re-assembly

- API 5L grades of conductor and structural casing ranging from 16” to 36” diameter

- Welding of casing to casing, casing to connector, casing to wellhead or casing to cement shoes and collars

These services are offered either through our workshops or on-site.

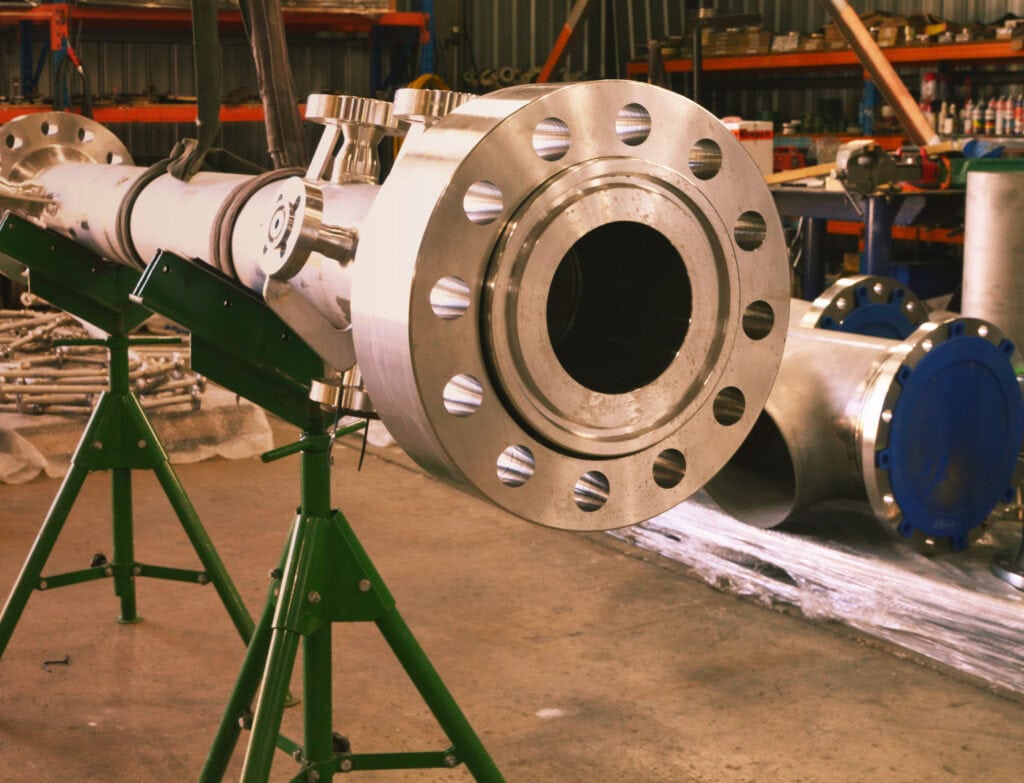

We offer factory acceptance (FAT) and system integration (SIT) testing of equipment such as:

- Test stumps

- Wellhead connectors

- Spools

- Flex joints

- Marine drilling risers

- Telescopic joints

- Riser handling spiders & gimbals

- Diverters

- Manifolds

- Riser adaptors

- Goosenecks and high pressure risers

Our team fabricates fuel and process skids, including pre-assembly and Factory Acceptance Testing (FAT). We specialise in metering, pressure reduction, and heating skids, delivering tailored solutions ready for immediate deployment.

We provide fabrication and remediation services for marine infrastructure, including FPSO and ship repairs, all in accordance with Lloyd’s register requirements Class 1, 2 or 3 for the maritime industry. We provide on and off-site marine repairs for Drilling Rigs, Jack Ups, Production Platforms and FPSO’s during construction or operation.

We respond quickly to emergency and breakdown situations or to planned construction, maintenance, and dry dock projects.

Specialising in heavy, bespoke, and complex fabrications, such as ‘T.K.Y’ assemblies and structures, we deliver custom solutions to meet the most challenging engineering requirements. We provide fabrication solutions for:

- General Structural Steel fabrication and modularisation

- Pressure vessels fabrication, refurbishment & repairs in acc. with AS1210 & ASME requirements

- Repairs for Pig Launcher/Receivers & Filter Vessels

Selected case studies

View allExplore other services

Explore other services and find the best solution for you.